We’re excited to announce that the latest information is now available on our new site, the Ginesys One Wiki!. Visit the site for up-to-date resources and insights. We look forward to continuing to support you there!

We’re excited to announce that the latest information is now available on our new site, the Ginesys One Wiki!. Visit the site for up-to-date resources and insights. We look forward to continuing to support you there!

Release Notes 11.118.4

Control

| Release Date | |

| HO Version | 11.118.4 |

| POS Version | 1.118.2 |

| Web Database Compatibility Version | 1.6 |

| Features & Enhancements | 02 |

| Bug Fixes | 00 |

| Navigation |

Features & Enhancements

Serial | Dev ID | Idea Tracker | Description |

|---|---|---|---|

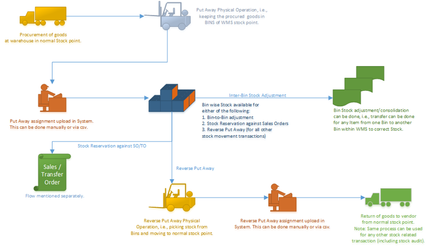

| 1 | 24060 | GIN-I 577 | GIN-I 577 Warehouse Management System introduced in GINESYS Head OfficeModule: Inventory - WMS - Setup - Bin Master Enhancement Summary: In a large warehouse, it is difficult to locate the stock of Items if system doesn't give any help of exact location. To enable this, GINESYS has introduced a module for managing the stock keeping areas, i.e., bins in the warehouse. Once bins are created in the system, for any organization site, the stock of the items can be put in or take out from those bins for any inward or outward transactions. For any disparity in the books as per the actual bin allocation, we have provided an option to do Bin adjustment. Stock from one bin can be transferred to another bin within same warehouse. Note: For any warehouse, only single WMS can be managed. Scenario: Whenever any inward transaction takes place in the organization site, the stock should be received in the warehouse type stock point and NOT in the WMS location. For example, whenever there is any Goods Receive, the stock should be received in QC stockpoint. Once QC is done, the approved stock should be moved from QC stockpoint to WMS location of the same site, i.e, allocate the stock to bins for storing the items. This process is called Put Away process, i.e., putting the items away in the bins. Whenever we need to dispatch the items, we need to take the items out from the bins and keep it in outward stock point. For example, If we want to make a goods return to the vendor, we will have to first take out the stock from the bins and put it in dispatch stockpoint. System will allow to make Goods Return from there. This process is called Take Away process, i.e., taking away items from bins. Due to physical operations, it might happen that an item gets wrongly placed as per the books. At this point, either books can be corrected or physically item can be placed to correct bin. If books needs to be corrected, Bin Adjustment module needs to be used, i.e., moving an Item between two bins of the same organization site. |

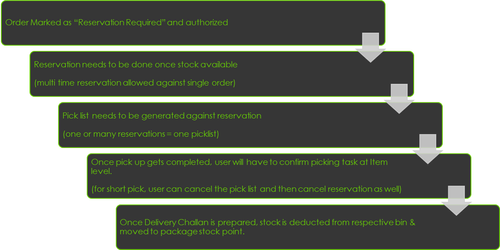

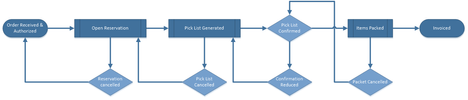

| 2 | 24060 | GIN-I 577 | GIN-I 577 Stock Reservation against Orders introducedModule: Admin - Organization Hierarchy - Organization Unit - Organization Site Enhancement Summary: At organization site level, administrators can provide the order fulfillment process for the site Once order is authorized and stock is available in the WMS location, it can be reserved both item wise and all order at once as well. Once order is reserved, a pick list can be generated and post confirmation of picking operation, it can be dispatched through our new delivery challan module. Scenario:

|